Extended Producer Responsibility on textiles effective in the Netherlands

August 01, 2023

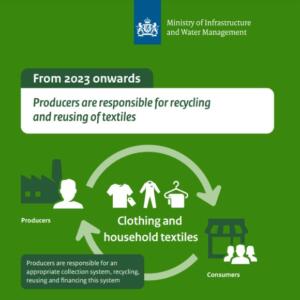

The textile industry is one of the most polluting industries in the world, accounting for, amongst others, staggering amounts of waste, environmental pollution, and resource depletion. Aiming to significantly reduce the sector’s ecological footprint, incentivise eco-conscious practices, and encourage sustainable innovation the Dutch government introduced Extended Producer Responsibility (EPR) regulation for textiles. The legislation is effective since July 1st 2023, and introduced under new regulations for waste management, recycling, and reuse of textile products, and makes manufacturers and retailers responsible for actively participating in the end-of-life management of their products.

With the introduction of the EPR, the Dutch government aims to recycle 50% of the Dutch market's release by 2025. By 2030, this should even be increased to 75%. Currently, only 35% of all textiles are being recycled.

Manufacturer's and retailer's responsibility for the entire lifecycle of their products

Extended Producer Responsibility (EPR) puts the producers and importers of products in charge of the entire cycle of their goods, including end of life stage. In this way, companies are encouraged to reuse or recycle materials and provide a large proportion of secondary raw materials for sustainable production.

The regulation applies to all companies that professionally offer textile products on the Dutch market, whether provided to a company (B2B) or to consumers, such as:

- Label/brand owners who are based in the Netherlands and control their production.

- (Online) retailers from the Netherlands who sell clothing/textiles under their label

- Importers of clothing/textiles to other companies

- Online retailers (based and stocked outside the Netherlands) who supply Dutch consumers (e.g. Amazon retailers).

Photo credits: Lena fashion library

Photo credits: Lena fashion library

Impact on businesses in the textile and fashion sector

The new regulation will have a big impact on the whole sector and different phases in the value chain, and actors in the sector are urged to educate themselves on the needed actions for their individual situations.

As in the Netherlands, EPR programmes are already in place for electronic waste (e-waste), batteries, car tyres and packaging materials; knowledge and experience from these product groups can be used by the actors in the textile sector.

Under the newly adopted regulation, the following obligations apply:

1. Organisation of an appropriate intake system

Producers must organise an ‘appropriate’ (available all year round and free) collection system for clothing and household textiles they place on the market. A producer organisation is expected to coordinate the collection on behalf of the producers, using the existing collection structure of municipalities (e.g. textile bins) for financial compensation. Currently, half of the textile waste ends up with residual waste and is used as a dressing. It is expected that old textiles can be returned to more locations, such as clothing stores, supermarkets and post offices.

2. Targets for reuse and recycling

From 2025, minimum targets for reuse and recycling will be increasing annually. For example, 50% in 2025 and 75% in 2030 of all textile waste in the Netherlands must be prepared for reuse or recycling. Specific targets for reusing textiles (such as second-hand clothing) exist. The aim is to encourage producers to market more high-quality textile products. These have a longer lifespan and can therefore be reused more easily. The new rules also prescribe that some textile waste must be reused in the Netherlands. This should reduce the dumping of textile waste in third countries.

3. Targets for textile fibre recycling

From 2025 onwards, annual minimum targets for fibre-to-fibre recycling will be increasing. This means that part of the recycled textile waste must be reused for clothing or household textiles (and therefore may not be used for insulation material, for example). This means that manufacturers will have to adapt their design and production methods for more use of recycled textile fibres in their textile products.

4. Annual report

Producers must report to the Minister of Infrastructure and Water Management every year on the number of textile products they have marketed in the Netherlands and on compliance with the obligations under the EPR textile regulations.

More information can be found here.

Global momentum for circular textiles

Growing momentum for sustainable practices in the fashion and textile sector can be seen globally. Countries such as France, Sweden, and Norway have already enacted similar textile EPR regulations, fostering an international commitment to collectively tackling fashion’s environmental challenges. The Green Deal Denim, where Dutch brands and retailers together with manufacturers in Turkey work together on a specified amount of denim products with a minimal amount of recycled material, is closely watched as this initiative can be an example for increased chain collaboration for sustainability and circularity. The Bangladesh textiles manufacturing industry, recently organised its first conference on circular apparel to set change in motion.

At the same time, the textile industry is witnessing inspiring examples of businesses leading the way. The mattress industry is a shining example. Traditionally, discarded mattresses have posed a significant waste management challenge, with many ending up in landfills. However, innovative companies like MattressRecycling.nl or Auping Circular Mattresses have adopted circular approaches to mattress manufacturing and end of life solutions.

Another success story is EMMA Safety Footwear, a brand specialising in sustainable safety shoes for workers. They incorporate eco-friendly materials, employ responsible production practices, and design durable footwear that can be recycled at the end of its life.

Many examples can be found in our publication ‘From linear to circular in the textile and apparel industry’ (see below).