Blue Phoenix Group – Building a Sustainable Future

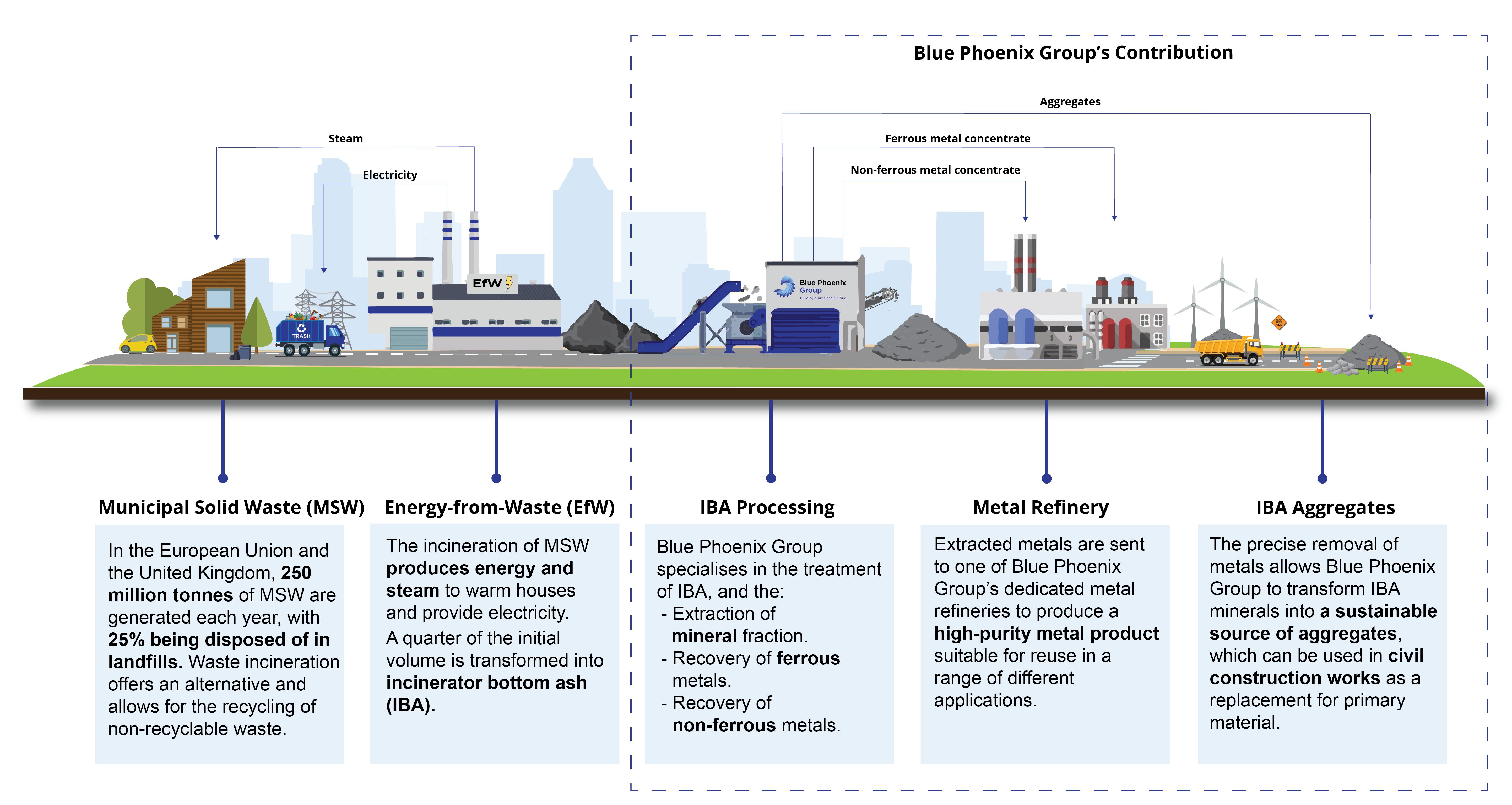

The increase in municipal solid waste (MSW) is a major environmental concern. Waste management technologies aim to recycle and minimise the environmental impact. Nevertheless, a significant proportion of our waste cannot be recycled. Incineration for energy recovery is an effective way to utilise the non-recyclable portion, reduce waste volume and reduce dependence on fossil fuels as an energy source.

Blue Phoenix Group operates the Incinerator Bottom Ash (IBA) installations globally and helps the Energy-from-Waste (EfW) sector with alternative sustainable solutions for ash residues. In addition, Blue Phoenix Group. process the IBA and extracts resources such as manufactured aggregates and metals that can be used as secondary materials contributing to the circularity of the sector.

“We must do what is necessary to give ash a new life and close the recycling loop for the Energy-from-Waste sector”

Blue Phoenix Group

State of the art waste transformation technology

Since 2008, Blue Phoenix Group has contributed to building a sustainable future in the EU, UK and USA. With a strong belief that waste does not exist, it offers custom solutions around the world to give ash a new life.

After the energy recovery process, about 25% of the initial waste volume remains as Incinerator Bottom Ash. Traditionally, this ash is transported directly to landfills, where it will stay for the rest of its life. Blue Phoenix Group is a strong proponent of the circular economy and has developed various technologies that allow this ash to be nearly 100% recycled and thus, give it a new life. They effectively separate the material into metals and minerals, which can be put back into the material economy, given their exceptional purity and performance.

The extracted metals, for example, can be re-used in the automotive or electronics sector. In addition, the aggregates can replace primary aggregates in road construction and concrete products, such as street tiles, pedestrian pavements and big blocks.

Besides investing heavily in Research & Development (R&D), Blue Phoenix Group prioritises minimising the environmental risk. Any proposed IBA applications come about in close consultation with environmental agencies. Blue Phoenix Group also has a dedicated environmental team in-house, which consists of several geo(hydro)logistics that study the long-time impact and behaviour of IBA in our environment.

Data Regarding Impact:

Improving the circularity of resources is at the core of Blue Phoenix Group’s business strategy. Circular economy is necessary to transition to a low carbon, sustainable future. Blue Phoenix Group process IBA from EfWs to produce aggregates in urban sites, preventing significant GHG emissions from resource extraction, production and transport.

For instance, compared to 10.000 tons of primary aggregates, recycled IBA aggregates prevent 80 trucks, each weighing 25 tonnes, off the road. In addition, the 20% avoided CO2 emissions add up to the annual energy usage of 3.6 homes. Globally, Blue Phoenix Group processes over 4,5 million tons of IBA, resulting in a large amount of emission saving potential.

Additionally, recycled IBA aggregates contribute to preserving nature since it lowers the need for primary mining materials. Finally, locally produced waste results in locally available recycled materials used in a city’s roads and pavements: a smart city concept to give ash a new life.