Circularity B.V. – The first completely 100% circularly produced product in the Netherlands

Circularity is a Netherlands-based circular fashion and workwear manufacturer that develops products made from old textiles, textile waste and stock lots.

The Company collects large clothing batches, such as: used clothing from industrial customers, sheets from hospitals or unsold items that would otherwise end up in the incinerator.

How did Circulatiry started

In 2014, Han Hamers, CEO of Circularity, started doing research in India about the textile recycling process. In 2018, after 4 years of research and development, a 100% recycled yarn made from textile waste was created. Afterwards, an idea emerged for them to open a circular textile manufacturing company in The Netherlands. In 2018 the planning started and the designing for fully automated stitching machines, and in June 2021 the factory doors opened in Etten-Leur.

The production process

After the textiles collection process, the bulk is stripped, disassembled and divided. This removes stitching and residual colors from the items. Zippers and buttons are removed from the articles. Then these stripped items go through the shredder. The Circularity machine ensures that the textile is made smaller and smaller until finally a bale of compressed textile pulp comes out. These fibers are spun into yarn and this yarn is knitted into cloth. Everything is fully automatic under the supervision of experts. The cloth is then cut into the right patterns and stitched together on fully automatic stitching tables. Optionally, the items can be printed or embroidered afterwards. This is followed by the folding and stacking process and the articles are prepared for transport.

Circularity's impact

Per kilo of clothing that is burned, 5.3 kilos of CO2 is released into the air. In 2020, 300 million textiles were burned in the Netherlands alone, which equates to 1.5 billion kilos of CO2 in the air.

By bringing circular economy principles into the textile sector, Circularity impacts the CO2 emissions. Moreover, considering that Circularity does not use any new raw materials for their clothing, the company makes less use of cotton, water, pesticides and oil.

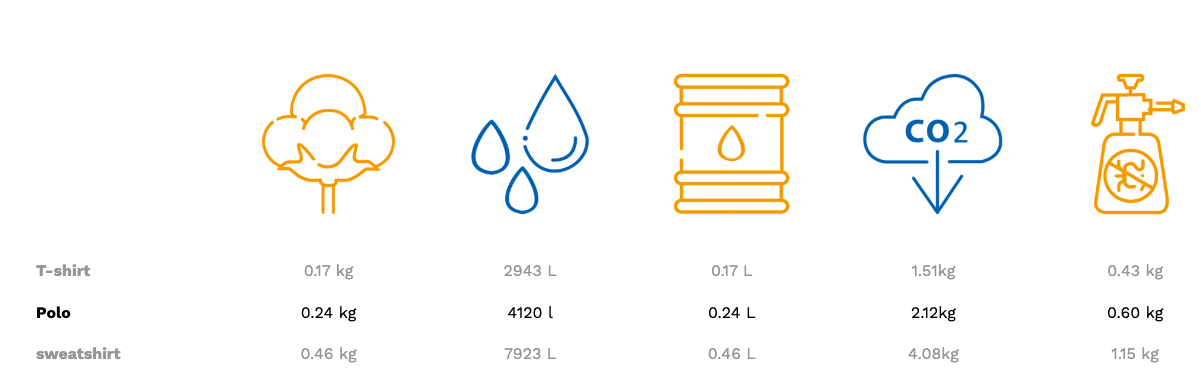

This is how much the Company saves per item in terms of cotton, water, oil, CO2 and pesticides: