Flocus(TM) kapok fiber the biodegradable and circular fiber that will help us plant more trees and regenerate the planet.

Flocus BV is a trademark for kapok fibers. Flocus ™ pioneers sustainable and regenerative textile solutions based on kapok fiber creates a responsible supply chain for kapok, and provides the textile industry with a naturally sustainable alternative that has not been available before. The company offers a range of kapok textile materials: fibers for stuffing, yarns, fabrics, nonwovens for thermo and sound insulation, waddings, foam replacement, medical, automotive, technical uses, and many more.

“Kapok trees are self-sufficient and produce a soft, silky fibre”.

Fashion United UK.

Natural source for sustainable and regenerative textile solutions

The business idea for Flocus came in 2014, when Jeroen Muijsers, a textile engineer, and his wife Sara Cicognani, came across Kapok and researched more about low-impact materials. Then in 2016, Flocus was founded after much RND and supply chain developments. Currently, Flocus holds a patent on the processing of kapok in textiles. Several companies and brands already utilize Flocus™ products, but they always strive for partners who can develop new customized products.

Flocus will open the very first CSR facility for kapok in the world by the end of 2021. A proper commitment is needed in terms of investment and innovation in agronomy, supply, and processing to secure a sustainable future for the industry.

The kapok industry is an ancient pride slowly dying because of new generations’ different goals and business interests. Therefore, there is a lack of a workforce. With the facility, Flocus will help the industry’s survival. They are committed to scaling the availability of kapok, aligning with associations that plant kapok trees to ensure steady growth. Furthermore, the industries where Flocus could advance and create new synergies include hygiene, construction, sound/acoustic, automotive and oil, industrial solutions, composites, and packaging.

Flocus work is in line with many of the Sustainable Development Goals of the United Nations, a blueprint for a better and more sustainable future for everyone.

It supplies the textile industry with a naturally regenerative and environmentally beneficial fiber, the only one which provides a carbon offset.

The Kapok trees:

Kapok trees do not need any irrigation water, pesticides, or fertilizers. They grow on poor and marginal and non-agricultural land, hills and store water, prevent soil erosion, and enhance biodiversity. The fiber is picked from the pod as a fiber form already, so no extra energy or water is applied in the processing. In comparison to an average tree that can absorb around 21 kg of carbon dioxide (CO2) per year, the kapok tree, because of its massive size (can grow up to 150- 200 feet tall and the trunk up to 10 feet wide), is calculated to absorb around 00 kg.

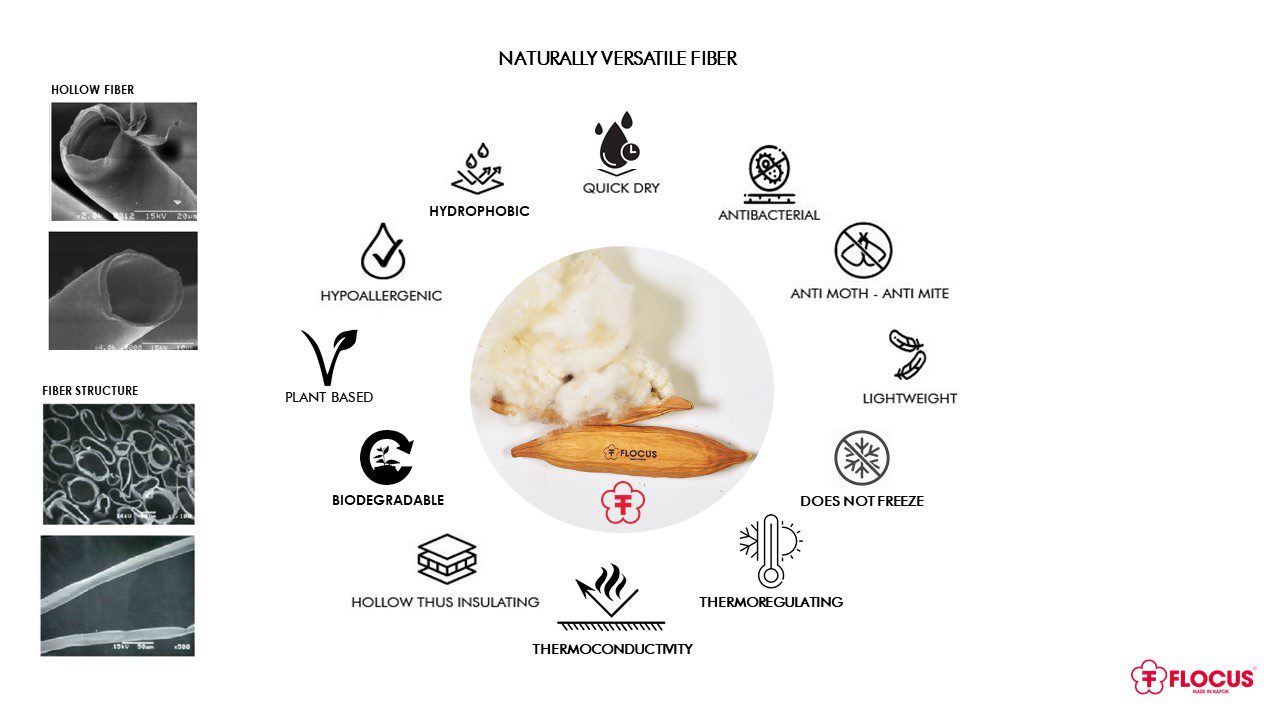

Kapok fiber is five times lighter than cotton because of its hollow structure, and its thermoregulation is the same or higher of feather down. In addition, because of its natural wax coating, it is hydrophobic, antibacterial, anti-moth anti-mite, and hypoallergenic.

For more information: www.flocus.pro